Should Rope Access Technicians Bring Their Own Gear? The Industry Debate Reshaping European Standards

The Dutch ZZP legislation is driving a major shift in European rope access practices. Companies now expect technicians to own their gear, but is this change beneficial for everyone? We examine the costs, benefits, and solutions reshaping the industry.

The rope access industry in Europe is experiencing a major shift. With the Dutch government enforcing stricter ZZP legislation from January 2025, companies are scrambling to ensure their contractor relationships meet the new independence criteria. One surprising outcome? More employers now expect rope access technicians to bring their own gear.

This isn't just another regulatory hiccup. It's reshaping how the entire industry operates, from Amsterdam to Athens. Whether you're a seasoned IRATA Level 3 supervisor or a company hiring rope access teams, this trend affects your bottom line, your safety protocols, and your competitive edge in the market.

The Regulatory Push Behind Equipment Ownership

Understanding the Dutch ZZP Laws and Their Impact

The enforcement of the DBA Act (Deregulation of Assessment of Employment Relationships) has turned the freelance world upside down. Starting January 1, 2025, Dutch tax authorities are actively checking whether freelancers are genuinely self-employed or should be classified as employees.

For rope access technicians, this means proving independence through nine key criteria, including financial risk-bearing, specialized expertise, and crucially—ownership of their own tools and equipment. The days of working exclusively for one company while using their gear are numbered. Tax authorities can now issue immediate corrections and retroactive assessments without warning, though fines won't kick in until 2026.

The message is clear: if you look like an employee, act like an employee, and use company equipment like an employee, you'll be taxed like one too. And that's expensive for everyone involved.

European Industry Standards and Equipment Requirements

European rope access work follows strict EN standards that don't mess around. According to regulatory requirements, PPE for rope access must meet EN361 for fall arrest, EN358 for work positioning, and EN813 for rope access harnesses.

But here's where it gets interesting: while standards dictate what equipment must be used, they don't specify who should own it. This gray area has become the battleground for the current debate. IRATA-certified technicians at all levels are already expected to be "responsible for own personal rope access equipment", suggesting the industry has been moving in this direction for years.

Current Industry Practices: A Regional Breakdown

The Netherlands and Northern Europe

Dutch companies are leading the charge in adapting to new realities. Total Industrial Support (Totalis), a major player in the Netherlands, already operates under IRATA guidelines where technicians maintain responsibility for their personal equipment. This isn't just about compliance—it's about staying competitive while avoiding the administrative nightmare of misclassification.

In Scandinavia, the trend mirrors the Dutch approach. Norwegian and Danish companies have long expected senior technicians to own their basic kit, viewing it as a mark of professionalism. The logic? A technician who invests in quality gear demonstrates commitment to the trade.

Global Perspectives

The equipment ownership debate looks different across the Atlantic. North American SPRAT-certified operations often see companies providing all equipment, viewing it as a safety and liability issue. Training facilities like PMI even loan equipment during certification courses, though they note that "students may bring their own rope access equipment for use in the class, if desired".

Meanwhile, emerging markets in Asia and the Middle East are watching European developments closely. Many adopt IRATA standards wholesale, which increasingly means accepting the equipment ownership model that's becoming standard in Europe.

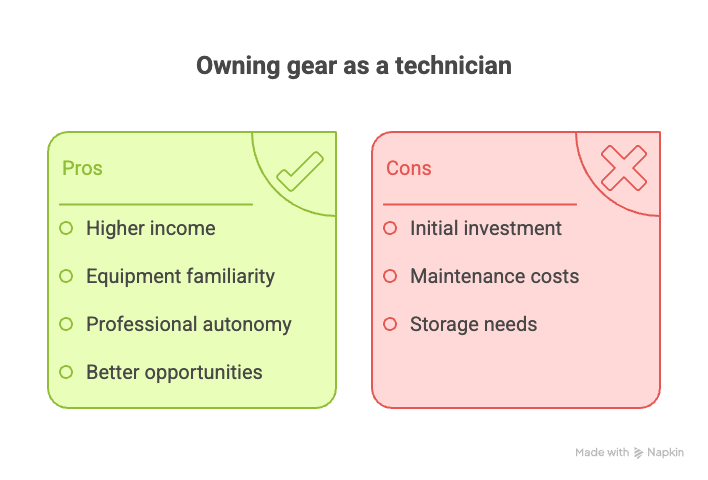

The Case FOR Technicians Owning Their Gear

Let's talk money first. Technicians who bring their own gear typically command 15-25% higher day rates than those who don't. On a typical €350 daily rate, that's an extra €50-85 per day. Over 200 working days, you're looking at €10,000-17,000 in additional annual income—far exceeding the initial equipment investment.

Equipment familiarity is another huge plus. When you work with your own harness every day, you know exactly how it fits, how it adjusts, and how it performs. You'll spot wear patterns immediately. You know your descender's quirks and your ascender's sweet spots. This intimate knowledge translates directly to safer, more efficient work.

Professional autonomy matters too. Own your gear, and you can accept last-minute contracts without waiting for equipment allocation. You're not tied to a single employer's equipment pool. This flexibility is exactly what the Dutch ZZP laws are designed to protect and encourage.

The Rope Access Network platform has recognized this trend, allowing technicians to indicate on their profiles that they have their own equipment. This feature helps employers quickly identify self-sufficient professionals who can start work immediately, while gear-owning technicians can access better opportunities and higher-paying contracts.

🧗 Rope Access Equipment ROI Calculator

See if owning your gear makes financial sense

💡 Pro tip: Technicians with their own gear typically earn 15-25% more per day in the Netherlands market.

€10,100

First Year Net Profit

The Case AGAINST Personal Equipment Requirements

Here's the uncomfortable truth: a basic IRATA-compliant kit costs between €2,000 and €5,000. That's a significant barrier for technicians just entering the field. Your shopping list includes a specialized harness (€300-600), helmet (€80-150), twin lanyards with energy absorbers (€150-250), descender and backup devices (€400-700), and various carabiners, slings, and accessories.

But purchase price is just the beginning. Equipment requires regular inspection, with harnesses and soft goods typically needing thorough examination every six months under LOLER regulations. Annual inspection and recertification costs can run €200-400, not counting replacements for worn items.

Insurance adds another layer of complexity. While professional liability insurance is standard, equipment coverage requires additional policies. Who's liable if personally-owned equipment fails? The legal waters get murky fast, and nobody wants to find out the hard way.

For new technicians, especially those from developing countries or career-changers, these costs create a real barrier. The industry risks losing diverse talent simply because the entry price has become too steep.

Making It Work: Solutions for Both Sides

Smart companies are finding middle ground. Some offer equipment purchase programs where technicians buy gear through the company at wholesale prices, paying through salary deductions. Others provide a gear allowance—typically €1,000-2,000 annually—that helps offset ownership costs while maintaining contractor independence.

Equipment leasing is gaining traction too. Technicians lease high-quality gear for €100-200 monthly, with options to purchase after 12-24 months. This spreads the cost while ensuring access to properly maintained, certified equipment.

The hybrid model shows promise: permanent employees use company equipment, while freelancers bring their own. This satisfies regulatory requirements while maintaining flexibility. Companies can offer "gear bonuses" to contractors without creating employment-like dependencies.

Platforms like Rope Access Network are facilitating this transition by clearly displaying equipment ownership status on technician profiles. This transparency helps companies find the right professionals quickly while ensuring technicians who've invested in gear get recognized for their professionalism.

Conclusion

The shift toward equipment ownership in rope access isn't going away. Driven by regulatory pressure and industry evolution, it's becoming the new normal in Europe. Smart technicians are viewing gear investment as exactly that—an investment in higher earnings and greater autonomy.

Companies that adapt creatively, offering support without creating dependency, will attract the best talent. Those that resist may find themselves on the wrong side of regulations or unable to compete for skilled technicians.

The rope access industry has always been about finding elegant solutions to complex problems. This equipment ownership challenge is just another problem to solve. With platforms like Rope Access Network connecting properly equipped technicians with companies that value professionalism, the industry will find its balance. The question isn't whether technicians should own their gear—it's how we make the transition work for everyone.

Frequently Asked Questions

What's the minimum equipment investment for a rope access technician starting out?

A basic IRATA-compliant kit costs between €2,000 and €5,000. Essential items include a certified harness meeting EN361/EN813 standards (€300-600), helmet (€80-150), and backup devices. Smart buyers start with quality basics and add specialized gear as contracts demand. Consider used equipment from reputable sources, but never compromise on harness and primary safety equipment.

How do the new Dutch ZZP laws affect rope access technicians specifically?

The DBA Act enforcement means technicians working primarily for one company risk being classified as employees rather than contractors. Owning your own equipment is one of nine criteria proving independence. Without it, companies face retroactive tax assessments and contractors lose their freelance status. The law particularly impacts technicians doing long-term maintenance contracts.

Can companies still provide equipment to contractors under the new regulations?

Yes, but carefully. Short-term equipment loans for specific projects are generally acceptable, but long-term provision suggests employment. Companies can offer purchase programs, wholesale access, or equipment allowances without creating dependency. The key is ensuring contractors maintain choice and financial responsibility for their gear.

What are the insurance implications when technicians use their own gear?

Personal equipment requires additional insurance coverage beyond standard liability policies. Technicians need equipment insurance covering damage, loss, and third-party liability. Costs run €200-500 annually depending on coverage. Companies should verify contractors carry adequate insurance and may need to adjust their policies to cover contractor-owned equipment use on their sites.

How can I indicate on my Rope Access Network profile that I have my own equipment?

Rope Access Network profiles include an equipment ownership indicator that employers can filter by when searching for technicians. Update your profile to show you own complete PPE, and list specific certifications (IRATA, SPRAT) and equipment types. This visibility helps you access better contracts and higher day rates, as employers know you're ready to start immediately without equipment delays.

Ready to Start Your Rope Access Career?

Join thousands of certified technicians on Rope Access Network. Create your professional profile, showcase your certifications, and connect with leading companies in the industry.